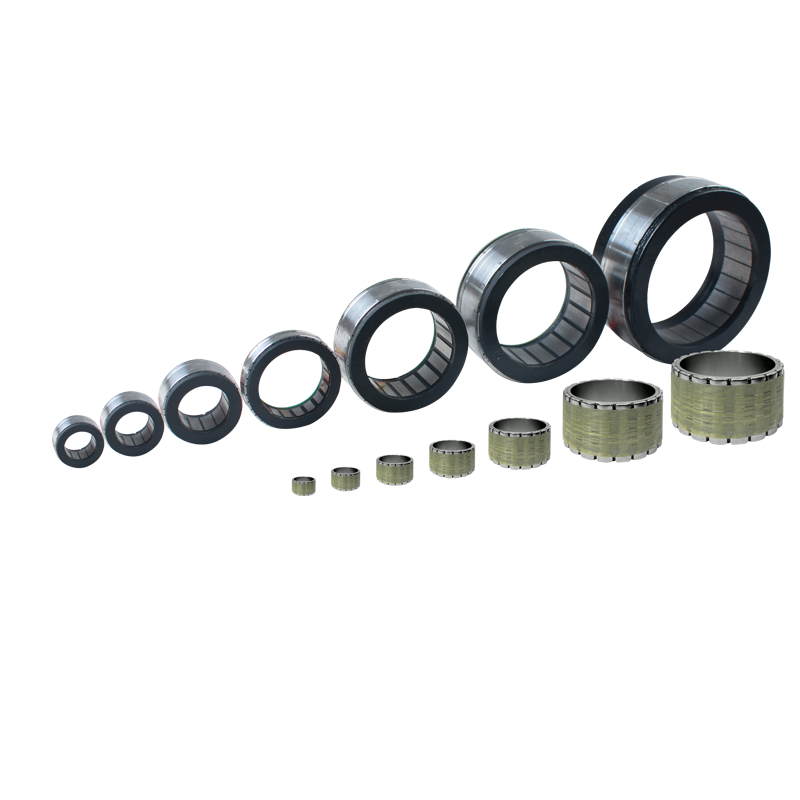

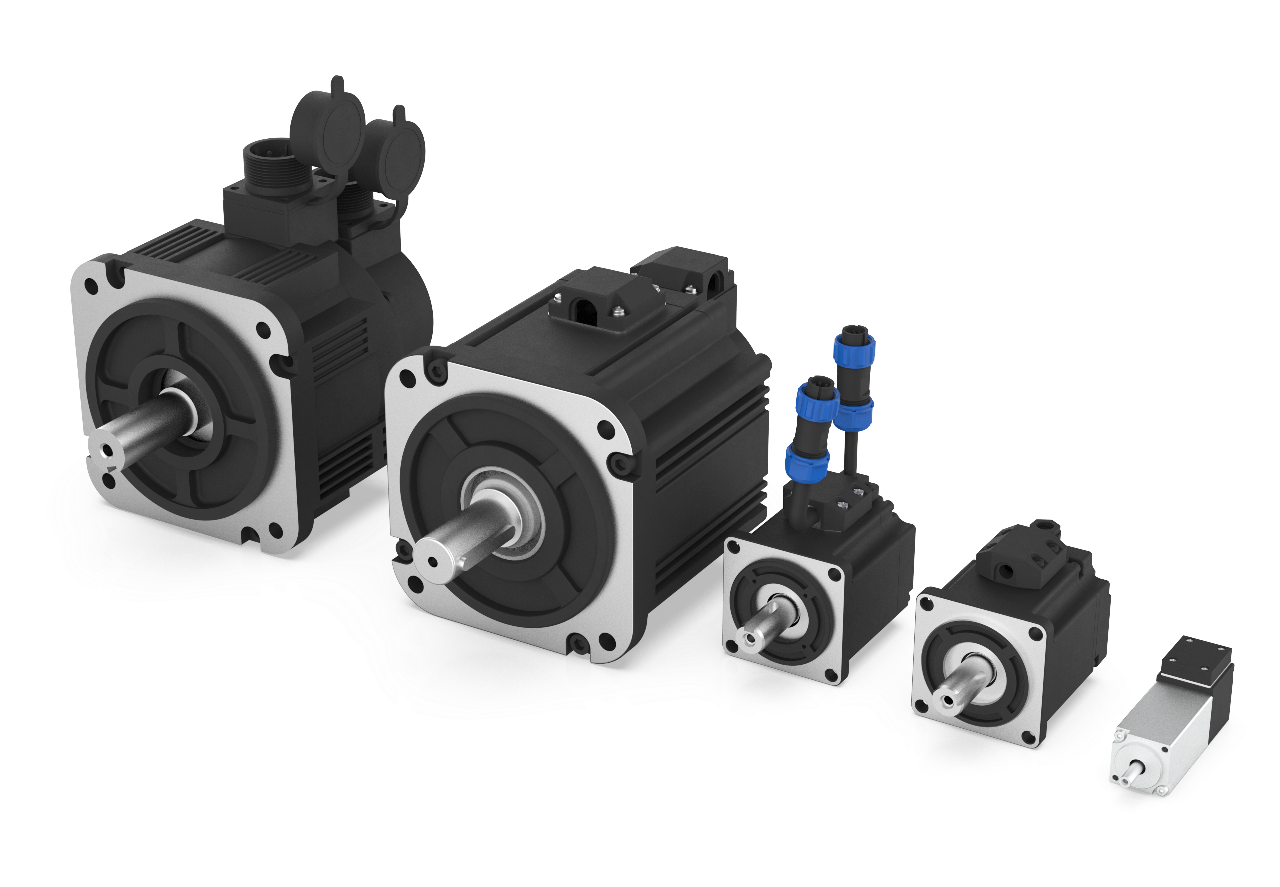

In today's manufacturing environment, precision, efficiency, and reliability are essential. At Leadshine, we see the BLDC servo motor as an important technology shaping the future of factory automation. Its brushless DC design provides smooth motion, accurate positioning, and consistent performance across a variety of industrial applications.

A BLDC servo motor delivers high efficiency while reducing heat generation and maintenance needs. This makes it ideal for applications like robotic arms, CNC machines, assembly lines, and packaging equipment, where consistent performance and minimal downtime are critical.

Benefits of a Servo Motor with Integrated Drive

For factories looking to simplify installation and save space, a servo motor with integrated drive is a practical solution. By combining the motor and drive into a single unit, it reduces cabling, simplifies system design, and improves reliability.

Leadshine's servo motor with integrated drive offers precise motion control with features such as high-velocity loop bandwidth, zero settling time, and vibration suppression. These integrated solutions make it easier for manufacturers to achieve accurate, efficient automation without complex setups. They are suitable for robotics, material handling, packaging, and automated inspection systems.

Applications Across Industries

The use of BLDC servo motor technology is growing across many industries. In assembly and packaging, it ensures smooth, synchronized motion that boosts productivity and reduces errors. In robotics, it enables fast, accurate movements. CNC machines benefit from improved precision and responsiveness, which enhances product quality.

Leadshine's solutions combine the performance of a BLDC servo motor with intelligent control to help manufacturers operate more efficiently. When paired with a servo motor with integrated drive, these systems are compact, easy to integrate, and reliable, supporting a wide range of automation needs.

Why Factories Are Adopting BLDC Technology

Factories are increasingly choosing BLDC servo motors because they provide consistent performance, lower maintenance, and energy efficiency. As production lines become more automated, the need for precise, reliable motion control grows.

Leadshine continues to develop servo motor with integrated drive solutions to meet these demands. Our products offer flexibility, precise control, and high performance, helping factories optimize operations, reduce downtime, and maintain product quality.

Conclusion

The BLDC servo motor represents a significant trend in factory automation, offering smooth motion, energy efficiency, and reliability. Combined with a servo motor with integrated drive, it delivers compact, high-performance solutions for a wide range of industrial applications.

At Leadshine, we focus on providing motion control systems that help manufacturers implement automation efficiently and effectively. By adopting BLDC technology, factories can improve productivity, maintain consistent quality, and prepare for the next generation of automated manufacturing.